1050 aluminium coiled chubhu

Zvinotsanangurwa

Yakajairika Kutsanangurwa kweAluminium chubhu

| Alloy Aihwa. | Temper | Straight Tube | LWC | ||

| OD(mm) | WT(mm) | OD(mm) | WT | ||

| 1060(L2) | R(H112) | 6~30 | 0.6~3 | 4~22 | 0.2~2 |

| M(O) | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H 14 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| 3A21 3003 3103 (LF21) | M(O) | 6~30 | 0.6~3 | 4~22 | 0.2~2 |

| H12 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H14 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H18 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| 6063 (LD31) | M(O) | 6~30 | 0.6~3 | 4~22 | 0.5~2 |

| T4 | 6~30 | 0.6~3 | 4~22 | 0.5~2 | |

| T6 | 6~30 | 0.6~3 | 4~22 | 0.5~2 | |

Tsanangudzo yeInner Groove Aluminium Tube (Saizi inogona kugadzirwa)

| Tsanangudzo(mm) | Kukora kwemadziro(mm) | Grooved Height(mm) | Helical angle (°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Mechanical Properties yeInner Aluminium Grooved Tube

| Material | Tensile | Elongation Rate | Kuwedzera Rate |

| 3003 | 130MPA | 35 | 40 |

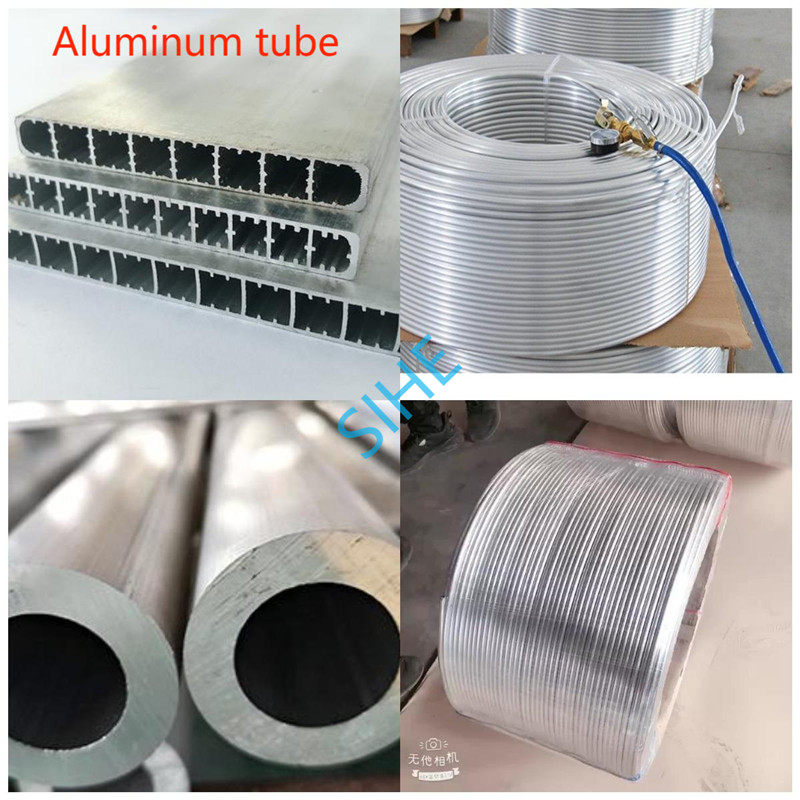

Tsanangudzo yePackage Coil

| OD | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Kukora Kwemadziro | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

quanlity gurantee

1) chitarisiko chepamusoro: furati yakachena nzvimbo isina kuzara, kukwenya, mafuta akasviba kana oxidation.

2) yekucheka kumucheto: yakarongeka yekucheka edge hapana burrs.

3) Hunhu chinangwa: frist chigadzirwa chekuongorora chinokodzera mwero i98%.kugutsikana kwemutengi ne95%.Material: A1050, A1060, A1070, A3003, zvichingodaro.

| A1050 Aluminium Chemical Kuumbwa | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Vamwe |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium Chemical Kuumbwa | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Vamwe |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Aluminium Chemical Kuumbwa | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Vamwe |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| A3003 Aluminium Chemical Kuumbwa | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Vamwe Vasina Kuroora | |

| vamwe | 0~0.6 | 0.05~0.20 | 0~0.1 | 1.0~1.5 | 0~0.70 | 0~0.05 | |

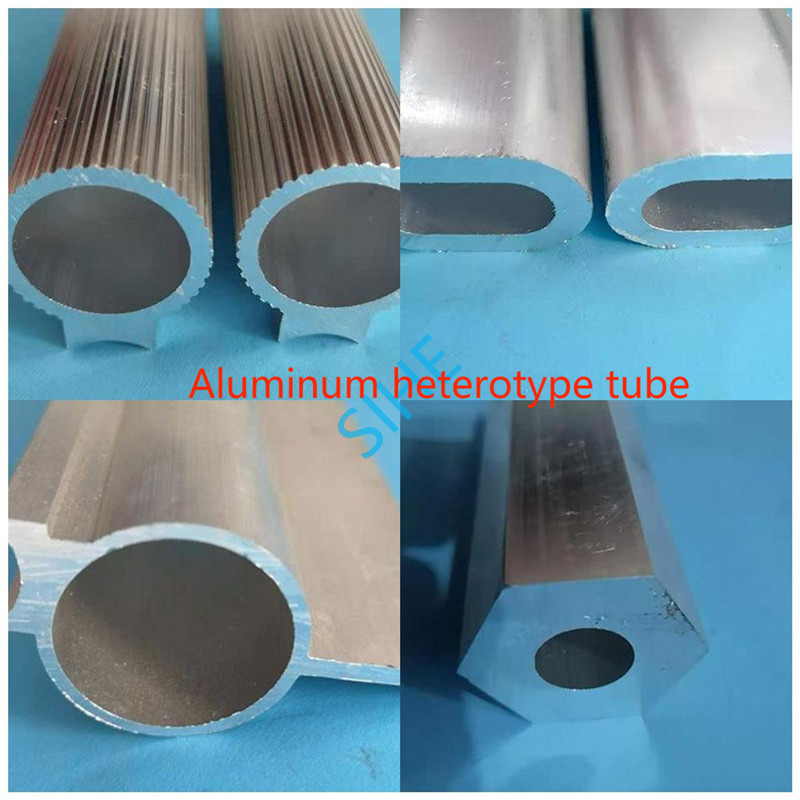

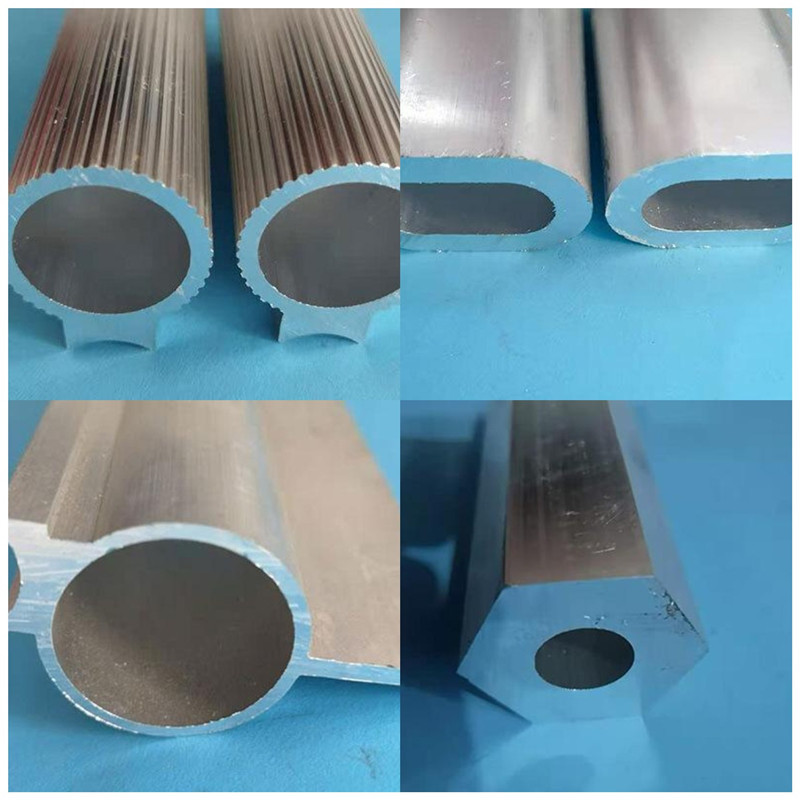

| Alloy | Temper | Tsanangudzo | |||

| Hukobvu(mm) | Dhayamita(mm) | Kusimba simba | Kuoma | ||

| 7075 7005(chubhu) | T5,T6,T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063(profile) | T5,T6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Kureba: <6Mita | |||||

| TEMPER | UKObvu(mm) | TENSILE SIMBA | ELONGATION% | Standard |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

Aluminium chigadzirwa

Nyora meseji yako pano uye titumire kwatiri