3003 aluminium coiled chubhu

3003 Inorevei MuAluminium Coil?

Nhamba dziri mualuminium coil ndiyo alloy code, inokuudza kuti zvii zviri mualloy.Nhamba yekutanga inoreva iyo inonyanya kukosha alloying element.Nhamba yechipiri inoratidza kusiyanisa kwealloy (kana yakasiyana ne zero), uye nhamba yechitatu neyechina inoratidza mutsara wayo.

Kune iyo 3003 aluminium coil, yekutanga digit '3' inoreva kuti ialloy mune manganese series, iyo '0' inoreva kuti haina mutsauko, uye nhamba yekupedzisira '03' zvinoreva kuti inobva mumutsara we3000.Ichi chirongwa chemanhamba chakavakirwa paInternational Alloy Designation System.

Zvivakwa zve3003 Alloy Aluminium Coil

3003 aruminiyamu coil ine kemikari inogumira 0.6 silicon, 0.7 iron, 0.05-0.20 mhangura, 1-1.5 manganese, 0.10 zinc, uye 0.15 kubva kune zvimwe zvinhu.

3003 aruminiyamu ine simba rekusimba rinosvika 200MPa, uye nzira dzese dzinokwanisa kuigadzira zviri nyore.Inoshingirira mukuora munzvimbo zhinji kunze kwekunge yaiswa mumvura yegungwa kana mamwe mamhepo anoora ane chlorine kana fluorine.

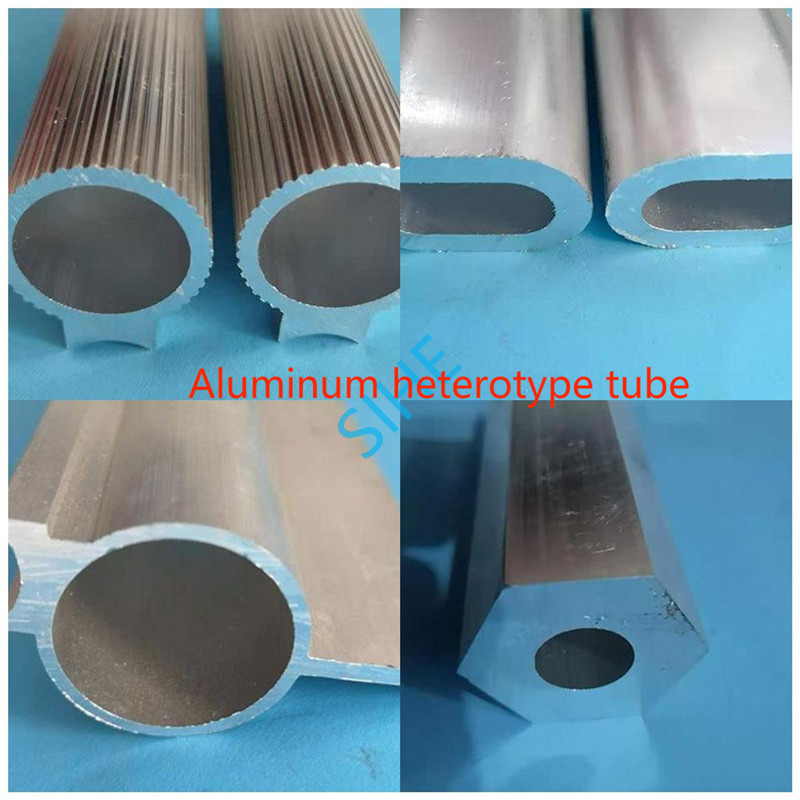

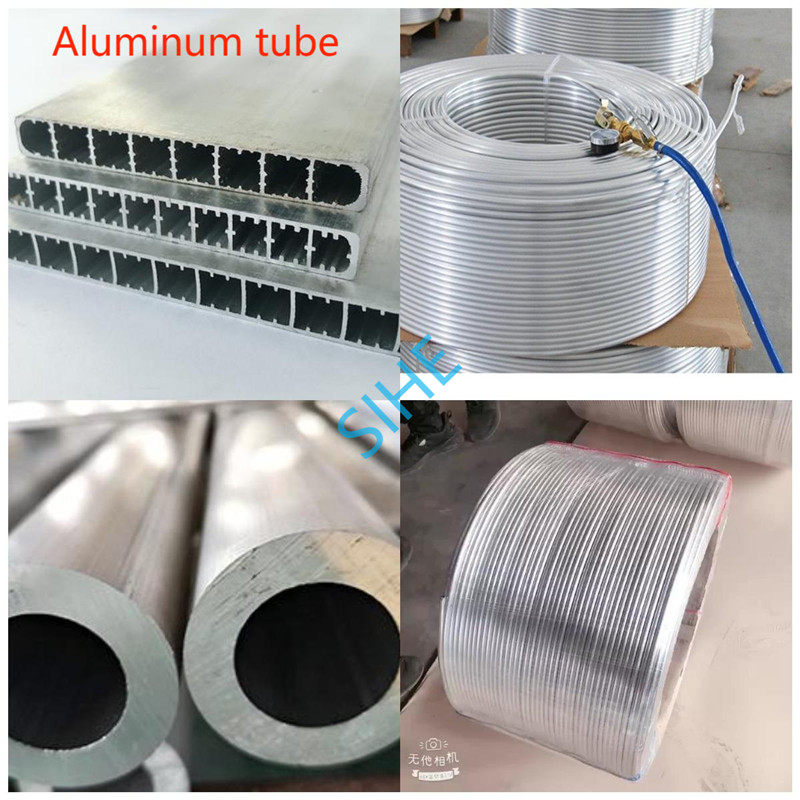

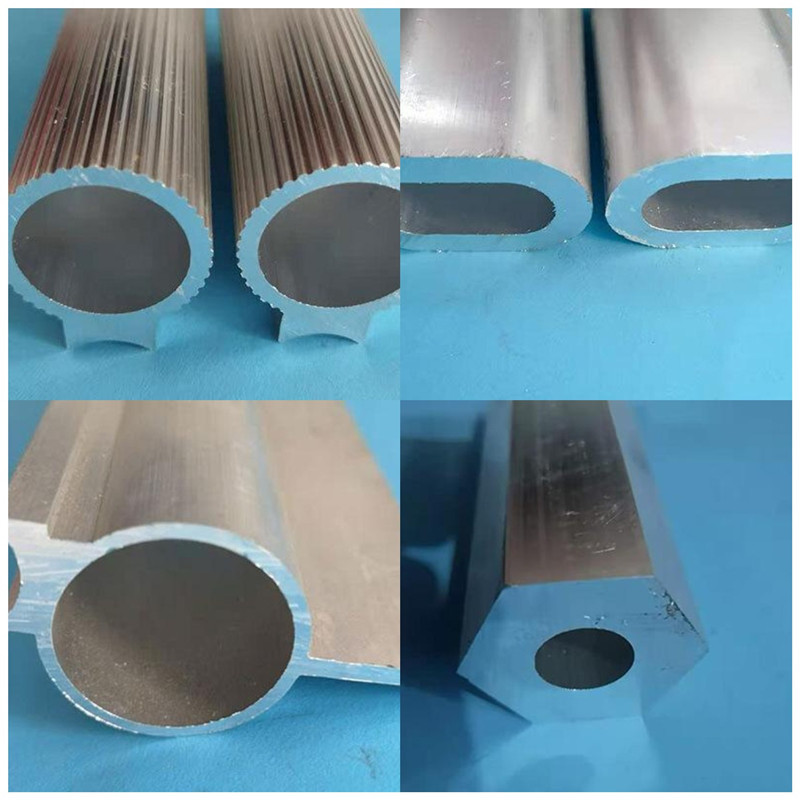

3003 alloy aruminiyamu makoiri anouya mumhando dzakasiyana uye saizi-kubva pamapepa angori 0.4 mm mukobvu kusvika 12 mm makobvu machubhu.Pane zvakawanda zvingasarudzwa paunenge uchifunga nezvezvinhu zvepurojekiti yega yega.Iwo anowanikwawo mumakoiri (ekushandiswa kwemaindasitiri) uye akatwasuka kureba (yezvirongwa zvekutengesa).

3003 Aluminium Coil Vs.3004 Aluminium Coil

3003 aruminiyamu coil uye 3004 aruminiyamu coil ese ari maviri anoshandiswa mukuwanda kwekushandisa.Kunyange zvazvo dzakafanana, hadzina kufanana, uye imwe neimwe ine zvayakanakira nezvayakaipira.

Iyo 3003 uye 3004 alloys yakafanana mukuumbwa, asi 3004 ine yekuwedzera 1% magnesium, ichiita kuti iwedzere kusimba.Izvi zvinokonzeresa kuramba kwecorrosion kuri nani kana yaiswa munzvimbo dzeasidhi, zvichiita kuti alloy iyi idhure kugadzira kupfuura 3003 alloys.

Iyo 3003 aruminiyamu alloy inopa zvirinani ductility pane 3004 alloy uye weldability nekuda kwekudzika kwayo magnesium content;zvisinei, ine yakaderera simba-ku-huremu reshiyo pane ekupedzisira zvinhu nokuda kwayo yakaderera density.

Nezvekushandiswa kwezvakatipoteredza, 3003 inogona kurapwa nekupisa uye kutonhora kushanda, asi 3004 inogona chete kutonhora kushanda.

Zvinotsanangurwa

| Alloy Aihwa. | Temper | Straight Tube | LWC | ||

| OD(mm) | WT(mm) | OD(mm) | WT | ||

| 1060(L2) | R(H112) | 6~30 | 0.6~3 | 4~22 | 0.2~2 |

| M(O) | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H 14 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| 3A21 3003 3103 (LF21) | M(O) | 6~30 | 0.6~3 | 4~22 | 0.2~2 |

| H12 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H14 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| H18 | 6~30 | 0.6~3 | 4~22 | 0.2~2 | |

| 6063 (LD31) | M(O) | 6~30 | 0.6~3 | 4~22 | 0.5~2 |

| T4 | 6~30 | 0.6~3 | 4~22 | 0.5~2 | |

| T6 | 6~30 | 0.6~3 | 4~22 | 0.5~2 | |

Tsanangudzo yeInner Groove Aluminium Tube (Saizi inogona kugadzirwa)

| Tsanangudzo(mm) | Kukora kwemadziro(mm) | Grooved Height(mm) | Helical angle (°) |

| 7 | 0.4-0.5 | 0.05-0.18 | 18 |

| 7.94 | 0.4-0.5 | 0.05-0.18 | 18 |

| 9.52 | 0.45-0.55 | 0.05-0.18 | 18 |

Mechanical Properties yeInner Aluminium Grooved Tube

| Material | Tensile | Elongation Rate | Kuwedzera Rate |

| 3003 | 130MPA | 35 | 40 |

Tsanangudzo yePackage Coil

| OD | 6.35 | 7.94 | 9.52 | 12.7 | 15.88 | 19.05 |

| Kukora Kwemadziro | 0.7-1.0 | 0.8-1,2 | 0.8-1.2 | 1-1.5 | 1-1.5 | 1-1.5 |

Quanlity Gurantee

| A1050 Aluminium Chemical Kuumbwa | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Vamwe |

| 99.5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium Chemical Kuumbwa | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Vamwe |

| 99.6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Aluminium Chemical Kuumbwa | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Vamwe |

| 99.7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| A3003 Aluminium Chemical Kuumbwa | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Vamwe Vasina Kuroora | |

| vamwe | 0~0.6 | 0.05~0.20 | 0~0.1 | 1.0~1.5 | 0~0.70 | 0~0.05 | |

| Alloy | Temper | Tsanangudzo | |||

| Hukobvu(mm) | Dhayamita(mm) | Kusimba simba | Kuoma | ||

| 7075 7005(chubhu) | T5,T6,T9 | >0.5 | 5.0-80 | >310 Mpa | >140 |

| 6061 6063(profile) | T5,T6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Kureba: <6Mita | |||||

| TEMPER | UKObvu(mm) | TENSILE SIMBA | ELONGATION% | Standard |

| T5 | 0.4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

| T6 | 0.5-6 | 70-120 | ≥ 4 | |

| T9 | 0.5-6 | 85-120 | ≥ 2 |

Aluminium chigadzirwa