Duplex Stainless Simbi - Superduplex

Musimbi, Stainless simbi ialloy yesimbi ine ingangoita 10.5% chromium ine kana isina zvimwe zvinosanganiswa zvinhu uye inokwana 1.2% kabhoni nehuwandu.Simbi dzisina tsvina, dzinozivikanwawo seinox simbi kana inox kubva kuFrench inoxydable (inoxidizable),simbi alloysizvo zvinonyatso zivikanwa nekusaita ngura, iyo inowedzera nekuwedzera chromium yemukati.Corrosion kuramba inogona zvakare kukwidziridzwa ne nickel uye molybdenum yekuwedzera.Kupokana kweaya esimbi alloys kune kemikari mhedzisiro ye corrosive agents kunobva pane passivation.Kuti passivation iitike uye irambe yakagadzikana, iyo Fe-Cr alloy inofanirwa kunge iine zvishoma chromium yemukati inosvika 10.5% nehuremu, pamusoro peiyo passivity inogona kuitika uye pazasi hazvigoneke.Chromium inogona kushandiswa sechinhu chinoomesa uye inowanzo shandiswa nechinhu chinoomesera chakaita se nickel kugadzira emhando yepamusoro michina.

Duplex Stainless Simbi

Sezvinoratidzwa nezita ravo, Duplex Stainless steels musanganiswa wemhando mbiri huru dzealloy.Vane microstructure yakasanganiswa ye austenite uye ferrite, chinangwa chinowanzova kubudisa musanganiswa we 50/50, kunyange, mumagetsi ekutengeserana, chiyero chinogona kuva 40/60.Kuramba kwavo kwekuora kwakafanana neao austenitic vamwe, asi kusagadzikana-kuora kwavo kusagadzikana (kunyanya kune chloride stress corrosion cracking), kusimba kwesimba, uye kuburitsa simba (zvinenge zvakapetwa kaviri simba regoho reaustenitic stainless steels) kazhinji rinopfuura iro reaustenitic. mamakisi.Mu duplex simbi isina tsvina, kabhoni inochengetwa kusvika yakaderera zvakanyanya (C <0.03%).Chromium yemukati inotangira pa21.00 kusvika 26.00%, nickel yemukati inotangira pa3.50 kusvika 8.00%, uye maalloys aya anogona kunge aine molybdenum (kusvika 4.50%).Kuoma uye ductility zvinowanzowira pakati peaya eaustenitic uye ferritic mamakisi.Duplex mamakisi anowanzo kupatsanurwa kuita matatu madiki-mapoka zvichienderana nekushomeka kwavo kwekuora: lean duplex, standard duplex, uye superduplex.Superduplex simbi dzakawedzera simba uye kuramba kune ese marudzi ekuora zvichienzaniswa neyakajairwa austenitic simbi.Kushandiswa kwakajairika kunosanganisira marine application, petrochemical plants, desalination zvidyarwa, zvinopisa kupisa, uye indasitiri yekugadzira mapepa.Nhasi, indasitiri yemafuta negasi ndiyo inonyanya kushandisa uye yakasundira kune mamwe magiredhi asingadzivirike, zvichitungamira mukugadzirwa kwesimbi dze superduplex.

Kupokana kwesimbi isina tsvina kune makemikari mhedzisiro ye corrosive agents kunobva pane passivation.Kuti passivation iitike uye irambe yakagadzikana, iyo Fe-Cr alloy inofanirwa kunge iine zvishoma chromium yemukati inosvika 10.5% nehuremu, pamusoro peiyo passivity inogona kuitika uye pazasi hazvigoneke.Chromium inogona kushandiswa sechinhu chinoomesa uye inowanzo shandiswa nechinhu chinoomesera chakaita se nickel kugadzira emhando yepamusoro michina.

Duplex Stainless Steels - SAF 2205 - 1.4462

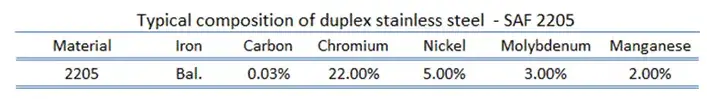

A common duplex Stainless steel is SAF 2205 (a Sandvik-owned trademark for a 22Cr duplex (ferritic-austenitic) Stainless steel), iyo inowanzo ine 22% chromium uye 5% nickel.Iyo ine yakanakisa corrosion kuramba uye yakasimba simba, 2205 ndiyo inonyanya kushandiswa duplex simbi isina tsvina.Zvikumbiro zveSAF 2205 zviri mumaindasitiri anotevera:

- Kutakura, kuchengetedza, uye kugadzirisa makemikari

- Processing midziyo

- High chloride uye nzvimbo dzemugungwa

- Oiri uye gasi kuongorora

- Paper machines

Zvivakwa zveDuplex Stainless Simbi

Material properties zvinhu zvakadzika, zvinoreva kuti zvakasununguka pahuwandu hwehuwandu uye zvinogona kusiyana kubva munzvimbo nenzvimbo mukati mehurongwa chero nguva.Sainzi yezvekushandisa inosanganisira kudzidza chimiro chemidziyo uye ichichibatanidza nemidziyo yazvo (makanika, magetsi, nezvimwewo).Kamwe sainzi wezvekushandisa angoziva nezve ichi chimiro-chivakwa kuwirirana, ivo vanogona kuzoenderera mberi nekudzidza hukama hwekuita kwechinhu mune yakapihwa application.Iwo makuru magadzirirwo echimiro chechinhu uye nekudaro chezvimiro zvayo ndiwo anoumba makemikari zvinhu uye kuti akagadziridzwa sei muchimiro chayo chekupedzisira.

Mechanical Properties yeDuplex Stainless Simbi

Zvishandiso zvinogara zvichisarudzwa kune akasiyana maapplication nekuti ane anodiwa masanganiswa emakanika maitiro.Kune zvimiro zvekushandisa, zvivakwa zvezvinhu zvakakosha uye mainjiniya anofanirwa kuzvifunga.

Simba reDuplex Stainless Simbi

Mune mechanics emidziyo, iyokusimba kwechinhundiko kugona kwayo kutsungirira mutoro wakaiswa pasina kukundikana kana deformation yepurasitiki.Simba rezvishandiso rinotarisa hukama pakati pemitoro yekunze inoshandiswa kune chinhu uye inoguma deformation kana shanduko muhukuru hwezvinhu.Simba rechinhu kugona kwayo kutsungirira mutoro uyu wakaiswa pasina kukundikana kana deformation yepurasitiki.

Ultimate Tensile Simba

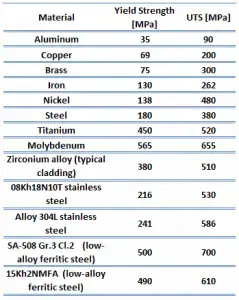

Iyo yekupedzisira kusimba kwesimba re duplex Stainless simbi - SAF 2205 ndeye 620 MPa.

Thekusimba kwekupedzisirandiyo yepamusoro pane engineeringstress-strain curve.Izvi zvinoenderana nekunyanya kunetseka kunotsigirwa nechimiro mukukakavadzana.Simba rekupedzisira rekusimba rinowanzopfupiswa kuita "simba rekusimba" kana "rekupedzisira."Kana kushushikana uku kuchishandiswa uye kuchengetwa, kuputsika kunoguma.Kazhinji, kukosha uku kwakanyanya kudarika kushushikana kwegoho (kusvika 50 kusvika 60 muzana kupfuura goho remamwe marudzi esimbi).Kana iyo ductile zvinhu inosvika pakusimba kwayo kwekupedzisira, inosangana nemutsipa uko iyo mhiri-chikamu nzvimbo inoderedza munharaunda.Iyo stress-strain curve haina kunyanya kushushikana kupfuura iyo yekupedzisira simba.Kunyangwe deformation inogona kuramba ichiwedzera, kushushikana kunowanzo kuderera mushure mekuwana simba rekupedzisira.Imba ine simba guru;saka, kukosha kwayo hakubvi pakukura kwemuenzaniso wekuedzwa.Nekudaro, zvinoenderana nezvimwe zvinhu, sekugadzirira kwemuenzaniso, kuvapo kana neimwe nzira yekuremara kwepamusoro, uye tembiricha yenzvimbo yekuyedza uye zvinhu.Ultimate tensile masimba anosiyana kubva pa50 MPa yealuminium kusvika pakakwirira se3000 MPa yesimbi yakasimba-yakanyanya.

Thekusimba kwekupedzisirandiyo yepamusoro pane engineeringstress-strain curve.Izvi zvinoenderana nekunyanya kunetseka kunotsigirwa nechimiro mukukakavadzana.Simba rekupedzisira rekusimba rinowanzopfupiswa kuita "simba rekusimba" kana "rekupedzisira."Kana kushushikana uku kuchishandiswa uye kuchengetwa, kuputsika kunoguma.Kazhinji, kukosha uku kwakanyanya kudarika kushushikana kwegoho (kusvika 50 kusvika 60 muzana kupfuura goho remamwe marudzi esimbi).Kana iyo ductile zvinhu inosvika pakusimba kwayo kwekupedzisira, inosangana nemutsipa uko iyo mhiri-chikamu nzvimbo inoderedza munharaunda.Iyo stress-strain curve haina kunyanya kushushikana kupfuura iyo yekupedzisira simba.Kunyangwe deformation inogona kuramba ichiwedzera, kushushikana kunowanzo kuderera mushure mekuwana simba rekupedzisira.Imba ine simba guru;saka, kukosha kwayo hakubvi pakukura kwemuenzaniso wekuedzwa.Nekudaro, zvinoenderana nezvimwe zvinhu, sekugadzirira kwemuenzaniso, kuvapo kana neimwe nzira yekuremara kwepamusoro, uye tembiricha yenzvimbo yekuyedza uye zvinhu.Ultimate tensile masimba anosiyana kubva pa50 MPa yealuminium kusvika pakakwirira se3000 MPa yesimbi yakasimba-yakanyanya.

Goho Simba

Kusimba kwegoho re duplex simbi isina tsvina - SAF 2205 ndeye 440 MPa.

Thegoho pointipfungwa iri pana astress-strain curveiyo inoratidza muganho wemaitiro elastic uye kutanga maitiro epurasitiki.Kusimba kwegoho kana kushushikana kwegoho ndicho chivakwa chenyama chinotsanangurwa sekushushikana uko chinhu chinotanga kukanganisa plastiki.Kusiyana neizvi, iyo goho poindi ndiyo inotangira nonlinear (elastic + plastiki) deformation.Pamberi pegoho poindi, zvinhu zvacho zvinokanganisa elastically uye kudzokera kuchimiro chayo chepakutanga kana kushushikana kwakaiswa kwabviswa.Kana imwe nguva yegoho yapfuura, chimwe chikamu che deformation chichava chekusingaperi uye chisingadzokeri shure.Mamwe masimbi nezvimwe zvinhu zvinoratidza maitiro anonzi goho point phenomenon.Kusimba kwegoho kunosiyana kubva pa35 MPa kune yakaderera-simba aruminiyamu kusvika kuhukuru kupfuura 1400 MPa yesimbi yakasimba-yakasimba.

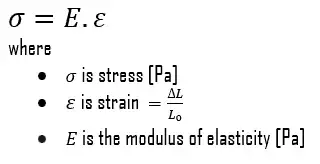

Mudiki's Modulus yeElasticity

Yechidiki modulus ye elasticity ye duplex Stainless simbi - SAF 2205 ndeye 200 GPa.

Young's modulus ye elasticityndiyo elastic modulus ye tensile uye compressive kusagadzikana mune mutsara elasticity regime ye uniaxial deformation uye inowanzoongororwa ne tensile bvunzo.Kusvika pakudzikamisa kushushikana, muviri unozokwanisa kudzoreredza zviyero zvawo pakubviswa kwemutoro.Kushushikana kwakaiswa kunoita kuti maatomu ari mukristaro afambe kubva panzvimbo yawo yakaenzana, uye zvesemaatomuvakadzingwa huwandu hwakafanana uye vanochengetedza yavo geometry.Kana zvinonetsa zvabviswa, maatomu ese anodzokera kunzvimbo yawo yekutanga, uye hapana deformation yekusingaperi inoitika.Maererano neMutemo waHooke, kushushikana kunoenzana nekunetseka (munzvimbo inoputika), uye kutsetseka ndiyo modulus yeYoung.Young's modulus yakaenzana nelongitudinal stress yakakamurwa ne strain.

Kuoma kweDuplex Stainless Steel

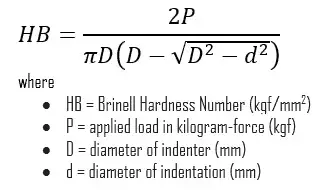

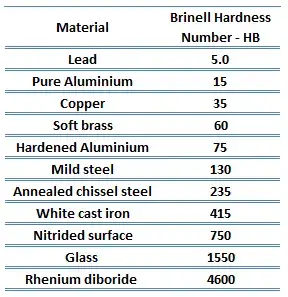

Brinell kuoma kwe duplex Stainless steels - SAF 2205 inenge 217 MPa.

Muzvinhu sainzi,kuomandiko kugona kushingirira indentation yepasi (localized plastic deformation) nekukwenya.Huoma ingangove ndiyo inonyanya kutsanangurwa zvisina kunaka midziyo nekuti inogona kuratidza kuramba kukwenya, kukwenya, kupinza, kana kunyangwe kuramba kuumbwa kana kugadzirwa kwepurasitiki.Kuomarara kwakakosha kubva pakuona kweinjiniya nekuti kuramba kupfeka nekukweshana kana kukukurwa nemhepo, mafuta, uye mvura zvinowanzowedzera nekuoma.

Muzvinhu sainzi,kuomandiko kugona kushingirira indentation yepasi (localized plastic deformation) nekukwenya.Huoma ingangove ndiyo inonyanya kutsanangurwa zvisina kunaka midziyo nekuti inogona kuratidza kuramba kukwenya, kukwenya, kupinza, kana kunyangwe kuramba kuumbwa kana kugadzirwa kwepurasitiki.Kuomarara kwakakosha kubva pakuona kweinjiniya nekuti kuramba kupfeka nekukweshana kana kukukurwa nemhepo, mafuta, uye mvura zvinowanzowedzera nekuoma.

Brinell kuomarara bvunzondeimwe ye indentation kuomarara bvunzo dzakagadzirirwa kuongororwa kuomarara.Mune bvunzo dzeBrinell, yakaoma, yakatenderera indenter inomanikidzwa pasi pemutoro chaiwo mukati mesimbi kuti iedzwe.Muyedzo wakajairika unoshandisa 10 mm (0.39 mu) dhayamita bhora resimbi rakaomeswa se indenter ine 3,000 kgf (29.42 kN; 6,614 lbf) simba.Mutoro unochengetwa nguva dzose kwenguva yakatarwa (pakati pe10 ne30 s).Nokuda kwezvinhu zvakapfava, simba duku rinoshandiswa;nokuda kwezvinhu zvakaoma, tungsten carbide bhora inotsiviwa nesimbi yesimbi.

Muedzo unopa mhedzisiro yenhamba yekuenzanisa kuomarara kwechinhu, icho chinoratidzirwa neiyo Brinell kuomarara nhamba - HB.Nhamba yekuomarara yeBrinell inotarwa nezviyero zvinonyanya kushandiswa (ASTM E10-14[2] uye ISO 6506–1:2005) seHBW (H kubva mukuoma, B kubva kuBrinell, uye W kubva kuzvinhu zveindenter, tungsten. (wolfram) carbide).Muzviyero zvekare, HB kana HBS yaishandiswa kureva kuyerwa kwakaitwa nesimbi.

The Brinell hardness number (HB) ndiwo mutoro wakakamurwa nepamusoro penzvimbo ye indentation.Kuwanda kwechiratidzo kunopimwa nemaikorosikopu ine chikero chakakwirira.Nhamba yekuoma kweBrinell inoverengerwa kubva kuequation:

Pane nzira dzakasiyana dzekuyedza dzinoshandiswa zvakafanana (semuenzaniso, Brinell,Knoop,Vickers,uyeRockwell)Kune matafura anowanikwa anowiriranisa huwandu hwekuoma kubva kune dzakasiyana nzira dzekuyedza uko kunoenderana kunoshanda.Muzvikero zvose, nhamba yekuoma kwepamusoro inomiririra simbi yakaoma.

Thermal Properties yeDuplex Stainless Simbi

Thermal properties of materials inoreva mhinduro yezvinhu kuchinja mune yavotembirichauye kushandiswa kwekupisa.Sechinhu chakasimba chinotorasimbamuchimiro chekupisa, kupisa kwayo kunokwira, uye zviyero zvayo zvinowedzera.Asi zvinhu zvakasiyana-siyana zvinosangana nekushandiswa kwekupisa zvakasiyana.

Kupisa simba,kuwedzera kwekushisa,uyethermal conductivitykazhinji dzinokosha mukushandiswa kwezvakaoma.

Melting Point yeDuplex Stainless Simbi

Iyo yekunyungudika ye duplex simbi isina tsvina - SAF 2205 simbi inotenderera 1450 ° C.

Kazhinji, kunyunguduka idanho rekuchinja kwechinhu kubva pachinhu chakasimba kuenda pachikamu chemvura.Themelting pointof a substance ndiyo tembiricha panoitika shanduko yechikamu ichi.Iyo yekunyungudika inotsanangurawo mamiriro apo iyo yakasimba uye mvura inogona kuvapo mukuenzana.

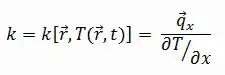

Thermal Conductivity yeDuplex Stainless Simbi

Iyo yekupisa conductivity ye duplex Stainless steels - SAF 2205 ndeye 19 W / (m. K).

Hunhu hwekutamisa kupisa kwechinhu chakasimba hunoyerwa nechinhu chinonzi thethermal conductivity, k (kana λ), kuyerwa neW/mK Inoyera kugona kwechinhu kufambisa kupisa kuburikidza nechinhu.conduction.Cherechedza kutiMutemo waFourierinoshanda kune yese nyaya, zvisinei nemamiriro ayo (yakasimba, mvura, kana gasi).Naizvozvo, inotsanangurwa zvakare kune zvinwiwa uye magasi.

Thethermal conductivityyezvinwiwa zvakawanda uye zvakaonda zvinosiyana netembiricha, uye pamhute, zvinoenderanawo nekudzvanywa.Kazhinji:

Zvishandiso zvizhinji zvinenge zvakafanana, saka tinogona kunyora k = k (T).Tsanangudzo dzakafanana dzinobatanidzwa nemafuta ekupisa mu y- uye z-directions (ky, kz), asi kune isotropic material, thermal conductivity yakasununguka kubva kune kutungamira kwekufambisa, kx = ky = kz = k.

Nguva yekutumira: Feb-04-2023