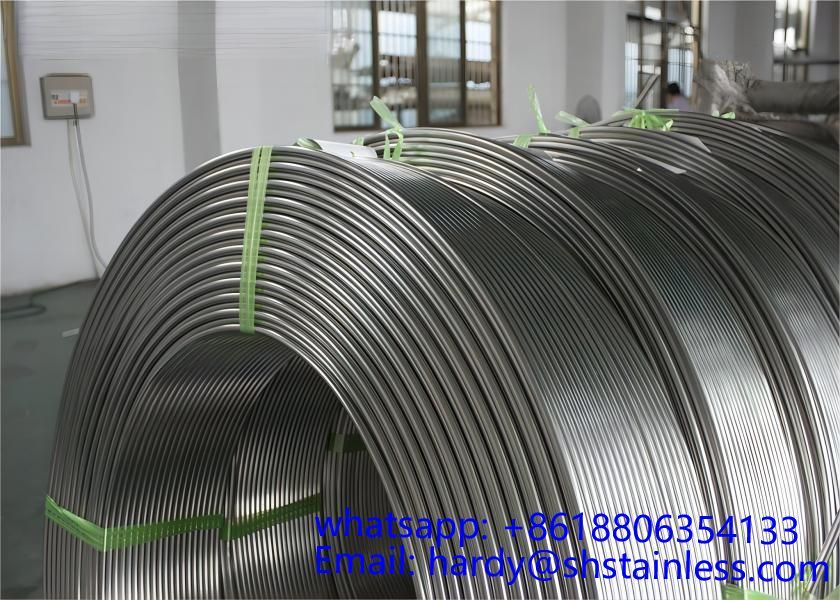

2507 simbi isina tsvina 10 * 1mm yakavharidzirwa capillary tubing

MATERIAL DESCRIPTION

2507 simbi isina tsvina 10 * 1mm yakavharidzirwa capillary tubing

Zvese zvedu super-duplex zvinhu zvinogadzirwa neNorsok M-650 Ed.4 uye/ kana ISO 17782 vagadziri vanokwanisa.

Super Duplex UNS S32750 ndiyo yakajairika super duplex giredhi pamusika.UNS S32750 ndeye duplex yakanyanya kugadzirirwa sevhisi munzvimbo dzine hukasha dzine chloride.Iyo ine yakanaka kwazvo kupikisa kune yenzvimbo corrosion uye kusagadzikana corrosion kuparuka pamwe chete nepamusoro mechanical simba.Inoshandiswa zvakanyanya muoiri & gasi, hydropower, midziyo yekumanikidza, pulp & bepa, zvimiro zvemukati uye makemikari matangi.

Applications

2507 simbi isina tsvina 10 * 1mm yakavharidzirwa capillary tubing

Iwo maapplications makuru ndeezvinyorwa zvine zvakakosha zvinodikanwa zvekudzivirirwa nekuora kwepamusoro.

UNS S32750 inoratidzwa ne:

- Kunyanya kupikisa kushushikana kuora kwekuputika mu halide ine nharaunda.

- High resistance kune gomba uye crevice corrosion.

- High resistance kune general corrosion.

- High mechanical simba.

- High resistance kune erosion corrosion uye corrosion kuneta.

Heat Treatment2507 Stainless simbi 10 * 1mm coiled capillary tubing

Solution annealing muhuwandu hwe1100 ° C ichiteverwa nekudzima kwemvura.

Weldability

Kugona chose.

2507 simbi isina tsvina 10 * 1mm yakavharidzirwa capillary tubing

Kemikari Inoumbwa (Yakanangana Nemabhawa)

| Huremu % | C | Mn | P | S | Si | Cr | Ni | Mo | Cu | N | PRE |

| Min. | 24,0 | 6,00 | 3,00 | 0,24 | 41 | ||||||

| Max. | 0,030 | 1,20 | 0,025 | 0,010 | 0,80 | 26,0 | 8,00 | 4,50 | 0,50 | 0,32 |

PREN = % Cr + 3.3 % Mo + 16 % N ≥ 41

Reference Standards

General:

- Norsok M-650 Ed.4 vagadziri vanokwanisa

- PED 2014/68/EU Annex I chikamu 4.3

- AD2000 W0 (W2/W10)

- NACE MR0175/ ISO 15156-3 uye NACE MR0103/ISO 17945

- 2507 simbi isina tsvina 10 * 1mm yakavharidzirwa capillary tubing

Plate, sheet uye coil:

- ASTM A240, EN 10028-7, EN 10088-2, EN 10088-4, Norsok M-630 MDS D55

Bar uye kugadzira:

- ASTM A276, ASTM A479, ASTM A182, EN 10088-3, Norsok M-630 MDS D54/D57

Zvimwe zvigadzirwa:

- Sezviri kushanda ASTM uye/kana EN zviyero uye Norsok M-630 MDS

Mechanical Properties (Yakajairika)

| Goho simba Rp0.2, MPa | Kusimba simba Rm, MPa | Elongation [%] | Kuoma [HB] | Impact, Charpy-V, -46ºC [J] | |

| BAR | ≥ 550 | ≥ 750 | ≥ 25 | ≤300 | ≥ 65 |

| PLATE CR (COIL) | ≥ 550 | 750 - 1000 | ≥ 25 | ≤ 310 | ≥ 45 |

| PLATE HR (COIL) | ≥ 550 | 750 - 1000 | ≥ 25 | ≤ 310 | ≥ 45 |

| NDIRO (QUARTO) | ≥ 550 | 750 - 930 | ≥ 25 | ≤ 310 | ≥ 45 |