Alloy 600 Stainless Steel Coil Tubing Mutengo

Kemikari Inoumbwa,%

Yakajairika corrosion application inosanganisira titanium dioxide kugadzirwa (chloride nzira), perchlorethylene syntheses, vinyl chloride monomer (VCM), uye magnesium chloride.Alloy 600 inoshandiswa mukugadzira makemikari uye chikafu uye kuchengetedza, kupisa kupisa, phenol condensers, sipo kugadzira, miriwo uye mafuta acid midziyo nezvimwe zvakawanda.

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 72.0 min | 14.0-17.0 | 6.0-10.0 | .15 max | 1.00 max | .015 max | .50 max | .50 max |

Ndeapi maapplication anoshandiswa Inconel 600?

- Indasitiri yemakemikari

- Aerospace

- Indasitiri yekurapa kupisa

- Pulp uye indasitiri yemapepa

- Kugadziriswa kwezvokudya

- Nuclear Engineering

- Gasi turbine zvikamu

ASTM Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Ndiro | Bar | Forging | Fitting | Waya |

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Mechanical Properties

Yakajairika tembiricha yekamuri Tensile Properties yeAnnealed Material

| Product Form | Condition | Tensile (ksi) | .2% Goho (ksi) | Elongation (%) | Kuoma (HRB) |

| Rod & Bar | Kunotonhora | 80-100 | 25-50 | 35-55 | 65-85 |

| Rod & Bar | Kupisa-Kupera | 80-100 | 30-50 | 35-55 | 65-85 |

| Tube & Pipe | Kupisa-Kupera | 75-100 | 25-50 | 35*55 | - |

| Tube & Pipe | Kunotonhora | 80-100 | 25-50 | 35-55 | 88 Max |

| Plate | Hot-Rolled | 80-105 | 30-50 | 35-55 | 65-85 |

| Sheet | Kunotonhora | 80-100 | 30-45 | 35-55 | 88 Max |

Inconel 600 Melting Point

| Element | Density | Melting Point | Tensile Simba | Goho Simba (0.2% Offset) | Elongation |

| Alloy 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi - 95,000 , MPa - 655 | Psi - 45,000 , MPa - 310 | 40 % |

Inconel 600 yakaenzana

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Alloy 600 | 2.4816 | N06600 | NCF 600 | NA13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

Alloy 600 Tubing

Alloy 600 mumiriri akanakisa kune akawanda mashandisiro mukupisa kwakanyanya uye nharaunda dzinoparadza zvakanyanya.Musanganiswa we nickel uye chromium unopa kuramba kwakasimba kune oxidation mukupisa kwekushanda.Iyi tembiricha inogona kubva ku cryogenic kusvika kune inopisa mazinga e2,000°F.Iyo yakakwira nickel yemukati yealloy 400 inopawo kunenge-kwakazara kuramba kushushikana nekuora kwekuputika, iyo inowanzowanikwa munzvimbo dzekloridi.

Zvakakosha kuziva kuti chikamu chechromium chechimiro chemakemikari alloy chinoita kuti giredhi rikwanise kumira kutonhora kwakanyanya.Iyo yakatsetseka yezviyo chimiro cheinotonhora yapera chubhu, nekuwedzera, inounza zvirinani corrosion kuramba, iyo inosanganisira kuneta kwakanyanya uye kukanganisa simba kukosha.

Zvigadzirwa Zvinotsanangurwa

ASTM B163, B167 / ASME SB163 / NACE MR0175, MR0103

Size Range

| Kunze Diameter (OD) | Kukora Kwemadziro |

| .250”–.750” | .035”–.083” |

Kemikari Zvinodiwa

Alloy 600 (UNS N06600)

Kuumbwa %

| Ni Nickel | Cu Mhangura | Fe Iron | Mn Manganese | C Carbon | Si Silicon | S Sulfur | Cr Chromium |

| 72.0 min | 0.50 max | 6.00–10.00 | 1.00 max | 0.15 max | 0.50 max | 0.015 max | 14.0–17.0 |

Dimensional Tolerances

| OD | OD Kushivirira | Kushivirira Kwemadziro |

| ≤ .500” kusanganisa | +.005” | ± 12.5% |

| .500”–.750” kusanganisa | +.005” | ± 12.5% |

Mechanical Properties

| Goho Simba: | 35 ksi min |

| Tensile Simba: | 80 ksi min |

| Elongation (min 2"): | 30% |

Fabrication

Alloy 600 inogona kuvezwa nyore nyore neyakajairwa maitiro.Iko kugona kweiyi alloy kwakanakisa, inogara pakati pekushandisa kweT303 uye T304.

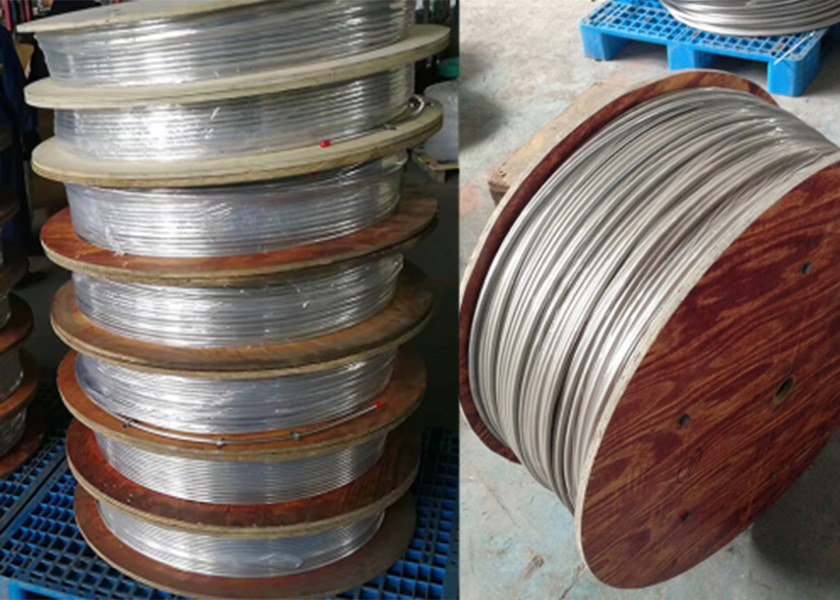

Mifananidzo ye Factory

Inspection

Kutumira & Packing

Test Report