Alloy 625 Stainless Steel Coil Tubing Mutengo

Kemikari Inoumbwa,%

Alloy 625 zvinhu haisi-magineti, austenitic, uye inoratidza yakakwirira tensile simba, kugadzirwa, uye brazeability.Nekuda kwekukwira kwayo nickel yemukati, iyi alloy inenge isingadzivirirwe kune chloride ion stress-corrosion cracking and pitting, iyo inowanzo wanikwa mumasimbi mumvura yegungwa semabatisi ekupisa, fasteners, uye tambo sheathing.

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

| 20.00-30.00 | Remainder | 8.0-10.0 | 1.0 max | 3.15-4.15 | .40 max | .40 max | .10 max |

| Fe | Mn | Si | P | S |

| 5.0 max | .50 max | .50 max | .015 max | .015 max |

Ndeapi maapplication anoshandiswa Inconel 625?

- Inconel 625 inonyanya kushandiswa muAerospace indasitiri

- Ndege ducting masisitimu

- Jet injini exhaust systems

- Engine thrust-reverser masisitimu

- Specialized mvura yegungwa michina

- Chemical process midziyo

ASTM Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Ndiro | Bar | Forging | Fitting | Waya |

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Mechanical Properties

| Temp° F | Tensile (psi) | .2% Goho (psi) | Elongation mu2 "(%) |

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

Inconel 625 Melting Point

| Melting Point | 1290 - 1350 °C | 2350 - 2460 °F |

Inconel 625 Yakaenzana

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4MNiCr22Mo9Nb | NiCr23Fe |

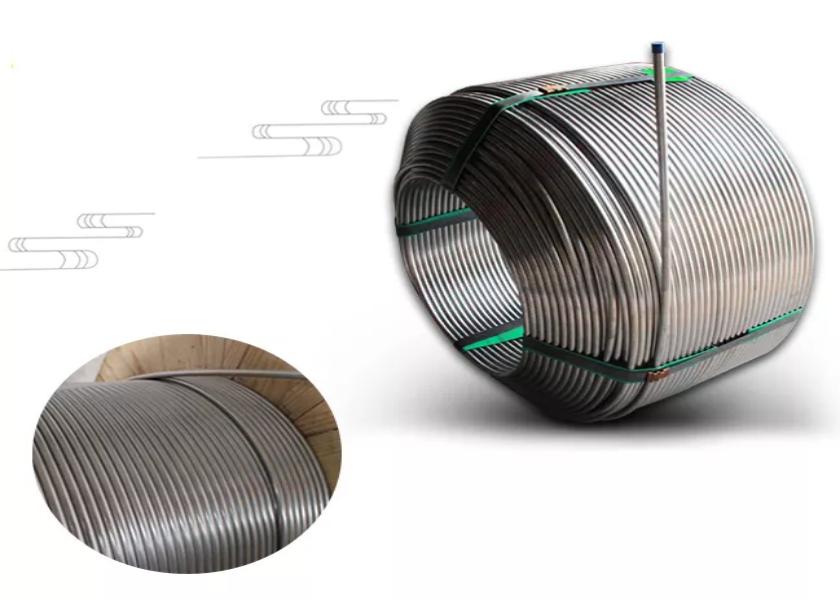

Alloy 625 Tubing

Alloy 625 is an austenitic nickel-chromium-molybdenum superalloy inozivikanwa nekusagadzikana kune crevice corrosion uye oxidation pane yakakwirira tembiricha.Tembiricha idzi dzinogona kubva ku cryogenic kusvika kumazinga ekupisa zvakanyanya e1,800°F.Maitiro uye kuumbwa kwemakemikari kwegiredhi iri kunoita kuti ive yakakodzera kune yenyukireya uye aerospace application.Zvakare, nekuwedzera kwe niobium, alloy 625 tubing inozviwana iine simba rakawedzera pasina kupisa kupisa.Ichi chivakwa chinoita giredhi sarudzo yakanaka yekugadzira.

Zvigadzirwa Zvinotsanangurwa

ASTM B444 / ASME SB444 / NACE MR0175

Size Range

| Kunze Diameter (OD) | Kukora Kwemadziro |

| .375"–.750" | .035”–.095” |

Kemikari Zvinodiwa

Alloy 625 (UNS N06625)

Kuumbwa %

| C Carbon | Mn Manganese | Si Silicon | P Phosphorous | Cr Chromium | Nb+Ta Niobium-Tantalum | Co Cobalt | Mo Molybdenum | Fe Iron | Al Aluminium | Ti Titanium | Ni Nickel |

| 0.10 max | 0.50 max | 0.50 max | 0.015 max | 20.0–23.0 | 3.15–4.15 | 1.0 max | 8.0–10.0 | 5.0 max | 0.40 max | 0.40 max | 58.0 min |

Dimensional Tolerances

| OD | OD Kushivirira | Kushivirira Kwemadziro |

| .375”–0.500” kusanganisa | +.004”/-.000” | ± 10% |

| 0.500”–1.250” kusanganisa | +.005”/-.000” | ± 10% |

Mechanical Properties

| Goho Simba: | 60 ksi min |

| Tensile Simba: | 120 ksi min |

| Elongation (min 2"): | 30% |

Mifananidzo ye Factory

Inspection

Kutumira & Packing

Test Report