Factors limited operating temps

Mashandisirwo akajairika anoda duplex zvinhu kuti zvionekwe kune yakakwirira-tembiricha midziyo yekumanikidza, fan blades / impellers kana exhaust gasi scrubbers.Zvinodiwa zvezvinhu zvenyama zvinogona kubva pakusimba kwemagetsi kusvika pakuonda.Makemikari emakiredhi anokurukurwa munyaya ino akanyorwa muTebhu 1.

Spinodal decomposition

Spinodal decomposition (inonziwo demixing kana nhoroondo se475 ° C-embrittlement) imhando yekuparadzaniswa kwechikamu muchikamu cheferritic, chinoitika pakupisa kunosvika 475 ° C.Mhedzisiro yakanyanya kutaurwa ndeye shanduko mune iyo microstructure, zvichikonzera kuumbwa kweiyo α' chikamu, izvo zvinoguma nekuputirwa kwezvinhu.Izvi, zvakare, zvinoderedza kushanda kwechigadzirwa chekupedzisira.

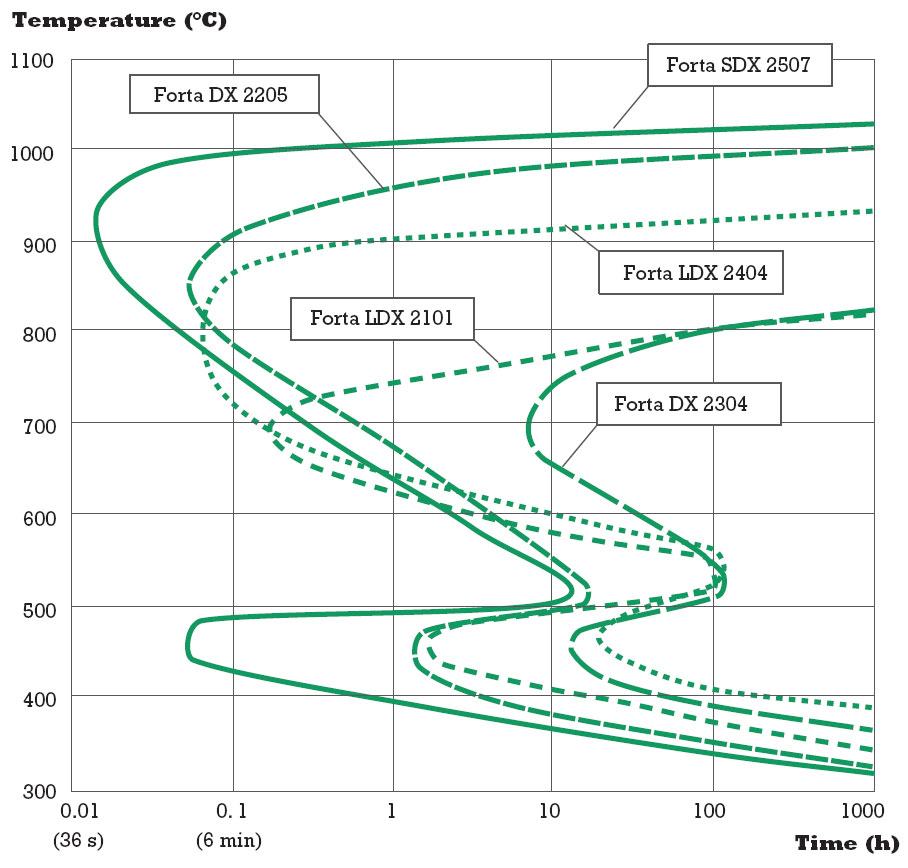

Mufananidzo 1 unoratidza tembiricha yenguva yekuchinja (TTT) dhayagiramu ye duplex zvinhu zvakadzidzwa, ine spinodal decomposition inomiririrwa mudunhu re475 ° C.Zvinofanira kucherechedzwa kuti dhayagiramu yeTTT iyi inomiririra kudzikira kwekuomarara ne50% kuyerwa nekukanganisa kuomarara kuyedzwa paCharpy-V specimens, izvo zvinowanzogamuchirwa sezvinoratidza kubvongodzwa.Mune mamwe maapplication kuderera kukuru kwekuoma kunogona kugamuchirwa, izvo zvinoshandura chimiro cheiyo TTT diagram.Naizvozvo, sarudzo yekuseta imwe yepamusoro yeOT inotsamira pane inoonekwa seyakagamuchirwa mwero wekupfutidza kureva kudzikiswa kwekuoma kwechigadzirwa chekupedzisira.Zvinofanira kutaurwa kuti nhoroondo TTT-magirafu akagadzirwawo pachishandiswa seti chikumbaridzo, akadai 27J.

Higher alloyed mamakisi

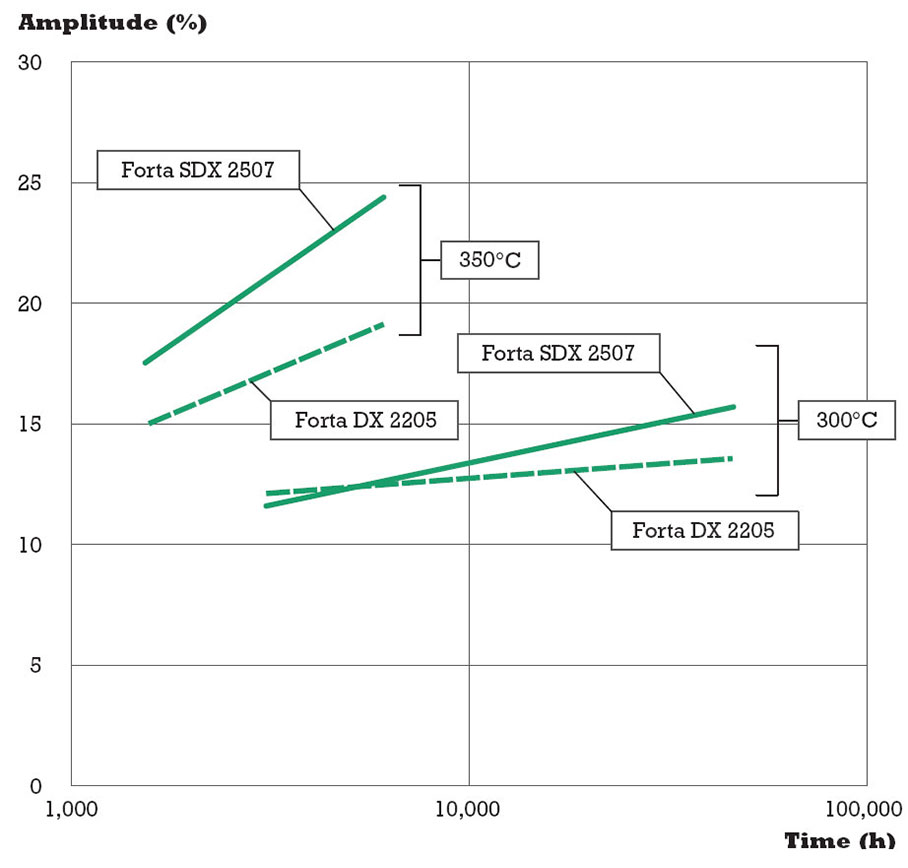

Mufananidzo 1 unoratidza kuti kuwedzera kwealloying zvinhu kubva kugiredhi LDX 2101 kuenda kugiredhi SDX 2507 kunotungamira kukurumidza kuora mwero, nepo lean duplex inoratidza kunonoka kutanga kwekuora.Kukanganiswa kwezvinhu zvinosanganiswa zvakadai sechromium (Cr) uye nickel (Ni) pakuora kwepinodal uye embrittlement yakaratidzwa nekuongorora kwakapfuura.5-8 Mhedzisiro iyi inotsanangurwa zvakare mumufananidzo 2. Inoratidza kuti kuparara kwepinodal kunowedzera kana kutonhora. inowedzerwa kubva pa300 kusvika pa350 °C uye inokurumidza kune yakakwira alloyed giredhi SDX 2507 pane shoma yakasanganiswa DX 2205.

Kunzwisisa uku kunogona kuve kwakakosha mukubatsira vatengi kusarudza pane yakanyanya OT inokodzera giredhi ravo rakasarudzwa uye kushandisa.

Kusarudza kupisa kwakanyanya

Sezvambotaurwa, iyo yakanyanya OT ye duplex zvinhu inogona kusetwa zvinoenderana nekudonha kunogamuchirwa mukuoma kwesimba.Kazhinji, OT inoenderana nehuwandu hwe50% kuomarara kuderedzwa inogamuchirwa.

OT zvinoenderana nenguva uye tembiricha

Kutenuka kuri mumiswe yemacurves mudhayagiramu yeTTT muFigure 1 kunoratidza kuti kuparara kwespinodal hakuitike chete pachikumbaridzo chimwe chete tembiricha uye kumira pazasi pedanho iroro.Asi, inzira inogara iripo kana duplex zvinhu zvichiratidzwa kune tembiricha yekushanda iri pasi pe475 ° C.Izvo zvakare zvakajeka kuti, nekuda kweiyo yakaderera kupararira mazinga, yakaderera tembiricha zvinoreva kuora kunotanga gare gare uye kuenderera zvishoma nezvishoma.Naizvozvo, kushandisa duplex zvinhu pazasi tembiricha zvinogona kusakonzera matambudziko kwemakore kana makumi emakore.Zvakadaro parizvino pane tsika yekuseta yakanyanya OT pasina kufunga nezvenguva yekuratidzwa.Mubvunzo unokosha ndewokuti ndeupi musanganiswa wekushisa-nguva unofanirwa kushandiswa kusarudza kana zvakachengeteka kushandisa chinhu kana kwete?Herzman et al.10 vanopfupisa dambudziko iri zvakanaka: "... Kushandiswa kunobva kwangoiswa kune tembiricha apo kinetics ye demixing yakadzikira zvekuti haizoitike panguva yehunyanzvi hwehupenyu hwechigadzirwa ...".

The impact of welding

Mazhinji maapplication anoshandisa welding kujoina zvikamu.Zvinonyatsozivikanwa kuti weld microstructure uye chemistry yayo inosiyana kubva kune base base zvinhu 3.Zvichienderana nefiller material, welding technique uye welding parameters, iyo microstructure ye welds inonyanya kusiyana kune yakawanda zvinhu.Iyo microstructure inowanzoita yakakora, uye izvi zvinosanganisirawo kupisa-kupisa kwakakanganiswa nzvimbo (HTHAZ), iyo inokanganisa kuparara kwepinodal mumasimbi.Musiyano we microstructure pakati pehuwandu uye weldments inyaya yakaongororwa pano.

Kupfupisa zvinhu zvinomisa

Zvikamu zvakapfuura zvinotungamira kune zvinotevera mhedziso:

- Zvese duplex zvinhu zviri pasi

kusvika pakuora kwespinodal patembiricha dzakapoteredza 475 °C. - Zvichienderana neiyo alloying yemukati, kukurumidza kana kunonoka kuparara mwero unotarisirwa.Yepamusoro Cr uye Ni yemukati inosimudzira kukurumidza demixing.

- Kuseta yakanyanya tembiricha yekushandisa:

- Kusanganiswa kwenguva yekushanda uye tembiricha inofanirwa kutariswa.

- Chiyero chinogamuchirika chekudzikira mukuomarara, kureva, nhanho inodiwa yekuomarara kwekupedzisira inofanira kusetwa - Kana mamwe ma microstructural components, akadai sewelds, akaunzwa, iyo yakanyanya OT inotarwa neiyo isina kusimba chikamu.

Global standards

Zviyero zvakawanda zveEurope neAmerica zvakaongororwa nezvechirongwa ichi.Ivo vakatarisa maapplication mumidziyo yekumanikidza uye pombi zvikamu.Kazhinji, mutsauko unoenderana neyakakurudzirwa yakanyanya OT pakati peyakaongororwa zviyero inogona kukamurwa kuita yeEuropean neAmerica maonero.

MaEuropean material specification standards for Stainless steels (semuenzaniso EN 10028-7, EN 10217-7) zvinoreva huwandu hweOT hwe250 °C nenyaya yekuti zvinhu zvenyama zvinongopihwa kusvika kune iyi tembiricha.Zvakare, iyo yeEuropean dhizaini miyero yemidziyo yekumanikidza uye pombi (EN 13445 uye EN 13480, zvichiteerana) haipe chero rumwe ruzivo nezve yakakwira OT kubva pane inopihwa mune yavo zvinhu zviyero.

Mukupesana, iyo yekuAmerica zvinhu zvakatemwa (semuenzaniso ASME SA-240 yeASME chikamu II-A) hairatidze chero yakakwira tembiricha data zvachose.Iyi data panzvimbo yakapihwa muchikamu cheASME II-D, 'Properties', inotsigira makodhi ekuvaka ezvikepe zvekumanikidza, ASME chikamu VIII-1 uye VIII-2 (iyo yekupedzisira inopa yakawedzera dhizaini nzira).MuASME II-D, iyo yepamusoro yeOT inotaurwa zvakajeka se316 °C kune akawanda duplex alloys.

Zvekumanikidza pombi maapplication, ese ari maviri dhizaini mitemo uye zvinhu zvivakwa zvinopihwa muASME B31.3.Mune iyi kodhi, mechanical data inopiwa kune duplex alloys kusvika ku316 °C pasina chirevo chakajeka chepamusoro OT.Zvakadaro, iwe unogona kududzira ruzivo kuti ruenderane nezvakanyorwa muASME II-D, uye nekudaro, iyo yakanyanya OT yezviyero zveAmerica mune kazhinji 316 °C.

Pamusoro peruzivo rwakanyanya rweOT, ese maAmerican neEuropean mwero anoreva kuti kune njodzi yekusangana nekumisikidzwa patembiricha yakakwira (> 250 ° C) panguva yakareba yekuratidzwa, iyo inofanirwa kutariswa mune zvese dhizaini uye sevhisi chikamu.

Kune ma welds, mazhinji mwero haaite chero chirevo chakasimba pamhedzisiro yekuora kwepinodal.Zvakadaro, mamwe mazinga (semuenzaniso ASME VIII-1, Tafura UHA 32-4) inoratidza mukana wekuita chaiwo post-weld kupisa kurapwa.Izvi hazvidiwe kana kurambidzwa, asi kana uchizviita zvinofanirwa kuitwa zvinoenderana neyakagadzikwa maparameter muchiyero.

Zvinotaurwa neindasitiri

Ruzivo rwakagadzirwa nevamwe vagadziri vakati wandei ve duplex simbi isina simbi yakaongororwa kuti vaone zvavanotaurirana maererano nematembiricha emagiredhi avo.2205 inogumira pa315 °C neATI, asi Acerinox inoisa Testamende yekare yegiredhi rimwechete pa250 °C chete.Iyi ndiyo miganho yekumusoro neyezasi yeOT yegiredhi 2205, nepo-pakati payo mamwe maOT anotaurirwa neAperam (300 °C), Sandvik (280°C) neArcelorMittal (280 °C).Izvi zvinoratidza kupararira kwemaOTs anokurudzirwa egiredhi rimwe chete anozove neakaenzana zvivakwa kubva kumugadziri kusvika kumugadziri.

Iyo yekumashure yekufunga kuti sei mugadziri akaisa imwe OT haiwanzo kuratidzwa.Kazhinji kazhinji, izvi zvinobva pane imwe mwero wakati.Mitemo yakasiyana inotaurirana maOTs akasiyana, nekudaro kupararira kwehunhu.Mhedziso ine musoro ndeyekuti makambani eAmerica anoisa kukosha kwepamusoro nekuda kwezvirevo muASME mwero, nepo makambani eEurope anoisa kukosha kwakaderera nekuda kweEN standard.

Chii chinodiwa nevatengi?

Zvichienderana nekushandiswa kwekupedzisira, mitoro yakasiyana-siyana uye kuratidzwa kwezvinhu zvinotarisirwa.Muchirongwa ichi, kubvongodzwa nekuda kwekuora kwespinodal kwainyanya kufarira sezvo kuchinyanya kushanda kumidziyo yekumanikidza.

Nekudaro, kune akasiyana maapplication anofumura duplex mamakisi kune epakati mechaniki mitoro chete, senge scrubbers11-15.Chimwe chikumbiro chaiva nechokuita nemashizha emhepo uye ma impellers, ayo anoratidzwa kuneta.Zvinyorwa zvinoratidza kuti kuora kwepinodal kunobata zvakasiyana kana mutoro wekuneta unoshandiswa15.Panguva ino, zvinova pachena kuti iyo yakanyanya OT yezvikumbiro izvi haigone kuiswa nenzira yakafanana neyekumanikidza midziyo.

Imwe kirasi yezvikumbiro ndeyekushandisa chete zvine chekuita nekuora, senge marine exhaust gas scrubbers.Muzviitiko izvi, corrosion kuramba kwakakosha kupfuura iyo OT kumisa pasi pemutoro wemuchina.Nekudaro, zvese zviri zviviri zvinokanganisa kushanda kwechigadzirwa chekupedzisira, icho chinofanirwa kutariswa kana chichiratidza iyo yakanyanya OT.Zvakare, nyaya iyi inosiyana kubva kune mbiri dzakapfuura.

Pakazere, kana uchiraira mutengi weiyo yakakodzera yepamusoro OT kune yavo duplex giredhi, iyo mhando yekushandisa ndiyo yakakosha pakuseta kukosha.Izvi zvakare zvinoratidza kuoma kwekugadza OT imwe chete yegiredhi, sezvo nharaunda iyo iyo zvinhu inoiswa ine mhedzisiro yakakosha pakuita kwe embrittlement.

Ndeipi yakanyanya kupisa tembiricha ye duplex?

Sezvambotaurwa, iyo yakanyanya tembiricha yekushanda inoiswa neiyo yakaderera kinetics yekuora kwepinodal.Asi tinoyera sei tembiricha iyi uye chii chaizvo chinonzi "low kinetics"?Mhinduro kumubvunzo wekutanga iri nyore.Isu takatotaura kuti kuyerwa kwekuomarara kunowanzoitwa kufungidzira mwero uye kufambira mberi kwekuora.Izvi zvakaiswa mumiyero inoteverwa nevazhinji vanogadzira.

Mubvunzo wechipiri, pane zvinorehwa necheki kinetics uye kukosha kwatinoisa muganhu wekushisa kwakanyanya kuoma.Izvi zviri muchikamu sezvo mamiriro emuganho ekunyanya tembiricha akaunganidzwa kubva kune ese ari maviri tembiricha (T) pachayo uye nenguva yekushandisa (t) iyo tembiricha inotsigirwa.Kusimbisa iyi Tt musanganiswa, kududzira kwakasiyana kweiyo "yakaderera" kuomarara kunogona kushandiswa:

• Muganho wepasi, uyo wakatarwa kare uye unogona kushandiswa kune welds ndeye 27 Joules (J)

• Mukati mezviyero kazhinji 40J inoiswa semuganhu.

• 50% kuderera kwekutanga kuoma kunoshandiswawo kakawanda kuisa muganhu wakaderera.

Izvi zvinoreva kuti chirevo chepamusoro cheOT chinofanira kunge chakavakirwa pane zvinokwana zvitatu zvakabvumiranwa fungidziro:

• Tembiricha-nguva kuratidzwa kwechigadzirwa chekupedzisira

• Hukoshi hwepasi hunogamuchirwa hwekuomarara

• Chikamu chekupedzisira chekushandisa (chemistry chete, mechanical load hongu/kwete etc.)

Yakabatanidzwa ruzivo rwekuedza

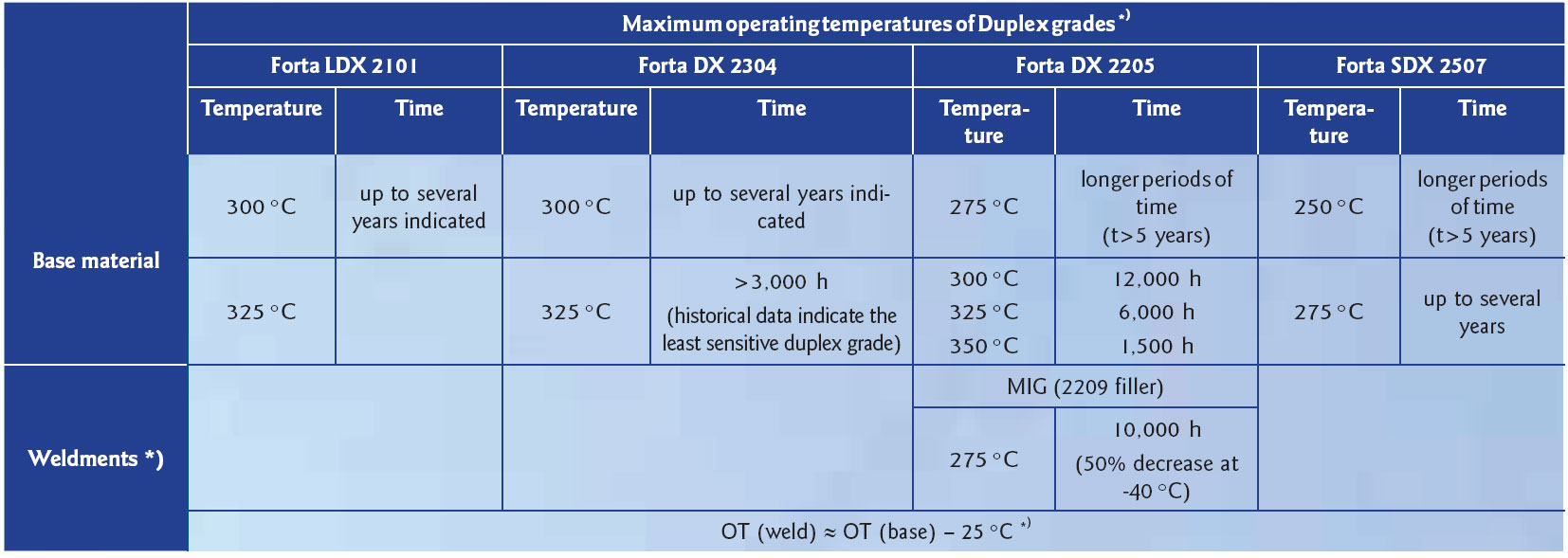

Zvichitevera ongororo yakadzama yedata rekuyedza uye mwero zvave zvichigoneka kuunganidza kurudziro kune mana duplex mamakisi ari kuongororwa, ona Tafura 3. Zvinofanira kucherechedzwa kuti yakawanda yedata inogadzirwa kubva mukuedza murabhoritari kwakaitwa nematembiricha e25 °C. .

Izvo zvinofanirwa kucherechedzwa kuti kurudziro idzi dzinotaura kune inokwana makumi mashanu muzana yekuomarara kwasara paRT.Kana patafura "nguva yakareba" inoratidzwa hapana kuderera kukuru paRT kwakanyorwa.Uyezve, iyo weld yakaedzwa chete pa -40 ° C.Chekupedzisira, zvinofanirwa kucherechedzwa kuti nguva yakareba yekuratidzwa inotarisirwa kuDX 2304, tichifunga nezvekuoma kwayo mushure memaawa zviuru zvitatu zvekuyedzwa.Nekudaro, kuti kuratidzwa kunogona kuwedzerwa kusvika papi kunofanirwa kusimbiswa nekumwe kuyedzwa.

Pane zvinhu zvitatu zvakakosha zvekucherechedza:

• Zvakawanikwa zvazvino zvinoratidza kuti kana mawelds aripo, OT inodzikira ne25 °C.

• Short term spikes (makumi emaawa paT=375 °C) anogamuchirwa kuDX 2205. Sezvo DX 2304 neLDX 2101 ari epasi alloyed mamakisi, anofananidzwa pfupi tembiricha spikes inofanira kugamuchirwa zvakare.

• Kana zvinhu zvakaputirwa nekuda kwekuora, kuderedza kupisa kwekurapwa pa550 - 600 °C yeDX 2205 uye 500 °C yeSDX 2507 kweawa imwe inobatsira kudzoreredza kusimba ne70%.

Nguva yekutumira: Feb-04-2023